Making a difference for our customers

435

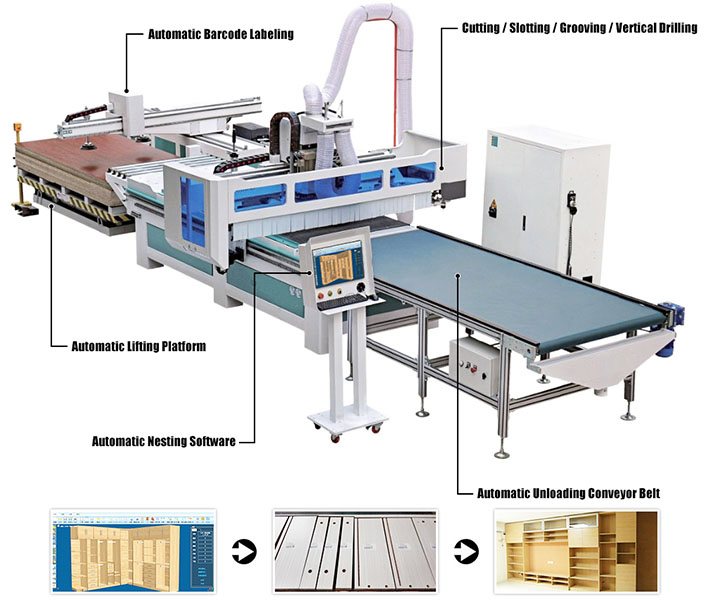

Model: WTM-1325FPL Category: Panel Furniture Production Lin

USD

45000$-68000$ FOB Qingdao

Professional manufacturer for Panel wooden furniture production line.Processing:engraving,cutting,drilling and edging.Is suitable for many materials,such as Materials such as plywood,MFC board and MDF board.

|

Model |

WTM-1325FPL auto feeding wooden furniture panel production line |

|

Working Area (X,Y,Z Axis) |

1300*2500*300mm (can be customized) |

|

Spindle |

Italy HSD air cooling spindles |

|

Drilling head |

5+4/HSD5+4 |

|

Software |

KD Cabinet design software (optional) |

|

Spindle Speed |

Adjustable 0-18,000 rpm |

|

Optional:Tool Changer |

Auto Tool-Change |

|

Working accuracy |

±0.02 |

|

Maximum Travel Speed |

60m/min |

|

Inverter |

FULING/delta |

|

Drive System (X & Y Axis) |

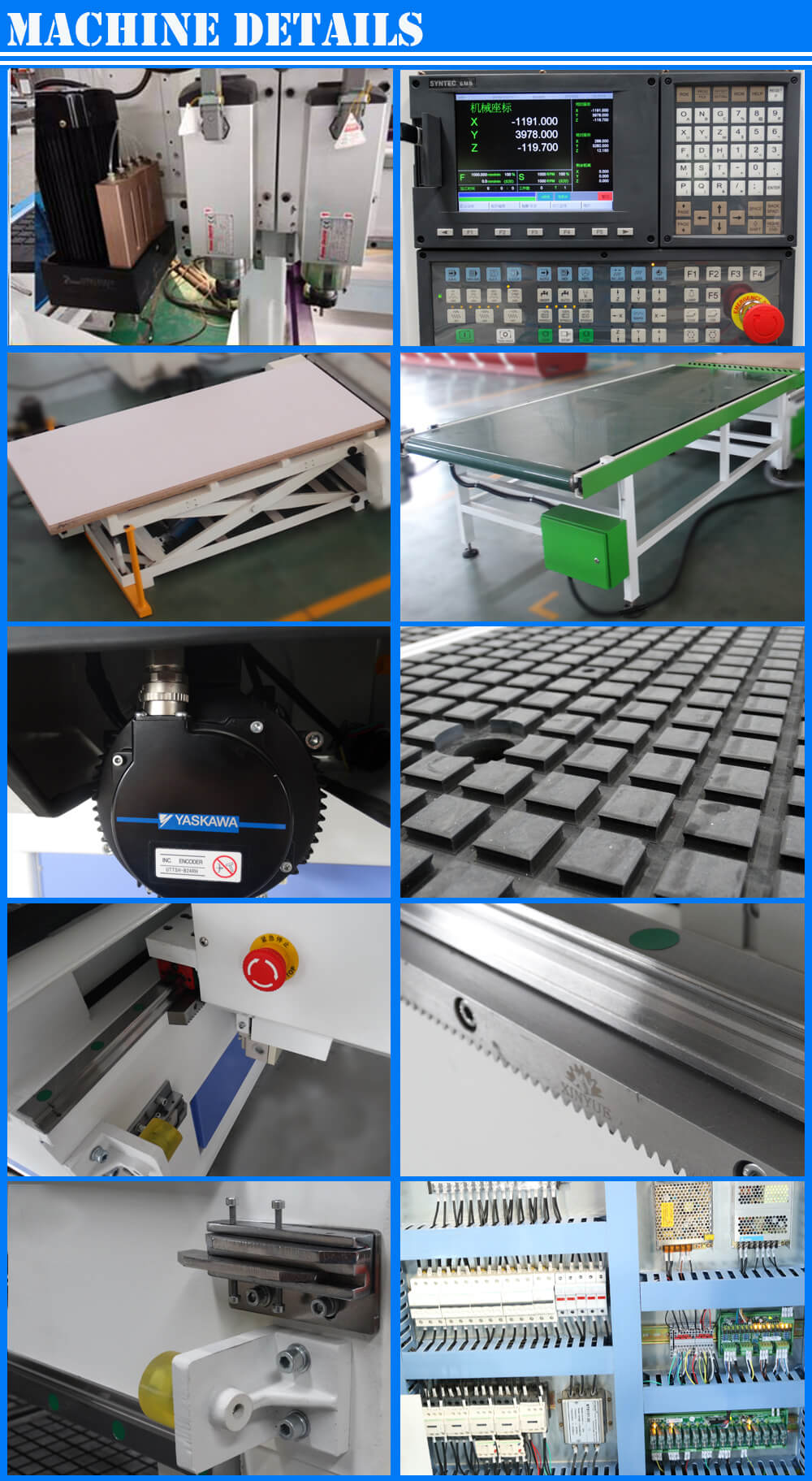

Rack and pinion transmission,Taiwan CSK square Guide rail |

|

Drive System (Z Axis) |

Taiwan TBI rolling ball screw,Taiwan CSK square guide rail |

|

Electrical parts |

Schneider |

|

Motor and Driver |

Japan Yaskawa Servo Motor and Drive |

|

Working table |

Vacuum table |

|

Vacuum pump |

7.5kw Water cooling |

|

Lubrication Systems |

Automatic oiling system |

|

Control system |

Taiwan Syntec control system |

|

Power Requirements |

AC380V/50HZ-3 Phase (Optional:220V) |

|

Command |

G code (HPGL,U00,mmg,plt) |

1.Good effect of processsing:High precision , cutting material very smoothly , Automatic design , automatic classification, without human intervention.

2.Improve work efficiency:Auto feeding materials, automatic layout optimization , improve material utilization.

3.Save working time:Automatic feeding , save the time of labor , no human intervention , minimizing error rate to minimum , ensure the quality of the order.

4.Japan YASKAWA or PANASONIC servo motor and driver, higher precision.

5. Break point memory can stop work with wrong signals and avoid the waste of materials.

6. Adopt high power 9KW air cooling spindle, which is suitable for long time and high temperature working.

7. Many optional configuration and OEM service are available.

If you need this wooden furniture production line, plesae feel free to like us.